E-mail: marketing@hbhuamei.com

Glass wool Sound Absorbing Foam panel, also called Acoustic Foam for Soundproofing or Sound Absorbing are soft sound absorption & energy-saving material by foaming with special techniques. It can absorb a large amount of incoming acoustic energy. To Reduce the interference and reverberation of the indoor reflections, and to improve the purity of sound. It is a high performance product for sound absorption and noise reduction.Soundproofing walls with foam is a great cheap way to get the job done on a budget.

Product Description

Echo absorbing materials-Cheap Sound Absorbing Foam are used to improve the sound quality inside of the room in which they are installed.

Products that are used to block sound are used INSIDE of the wall or ceiling - as part of the They can be dense, heavy materials or materials that will decouple the wall assembly - and due to their density, often reflect the sound back into the room rather than the sound penetrating through to the other side.

Glass wool Sound Absorbing Foam or acoustic glass fibre is lightweight and has excellent sound absorption properties even at low densities. Glass wool is made by a unique process, as the fine glass fibres trap small amounts of air, resulting in a reliable insulating material that is very good at absorbing high and medium frequency sound. HUAMEI has become a reference quality manufacturer of Glass wool Sound Absorbing Foam.

Good noise reduction effect on low and high frequency band sound

Good flexibility, not easy to break after repeated bending

Health and environmental protection, harmless to human body, no fiber pollution, no odor

Class B1 flame-retardant products

Light weight, can be cut at will, convenient construction

Beautiful appearance, convenient for design and decoration

Soundproofing Foam Blocks and Absorbers

Sound frequencies can be tricky to completely absorb or block. With the use of absorbers, you can achieve a better result in rooms both small and large when dealing with low frequencies. Since lower frequencies tend to be longer and they carry further, the use of absorbers is a great way to combat this concern. Offered in shapes such as rectangle, cube, and male/female sets, these foam pieces are ideal for placement in the corners of rooms to absorb sounds.

Ceiling Tiles

Part of creating the best sound space possible is by looking at the area as a whole. While many people will cover the walls with sound dampening foam, the ceiling is sometimes forgotten. This crucial area can be utilized to help improve function with our ceiling tiles. Available in both smooth and textured patterns, this type of foam can add extra sound dampening properties to any space.

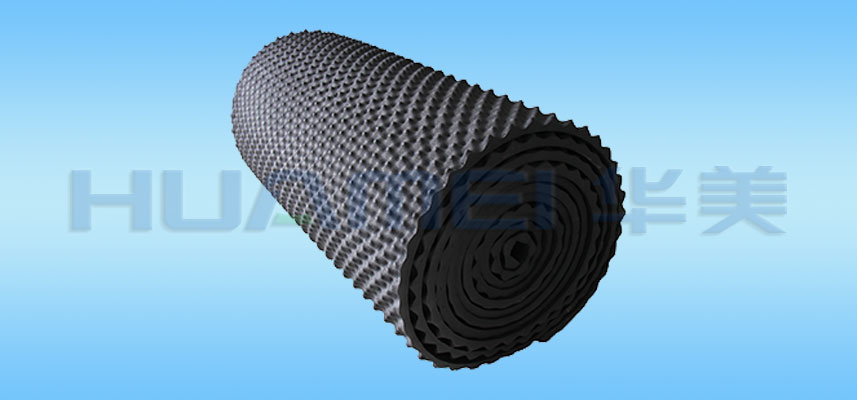

Closed-cell rubber foam sound-absorption panel

Placing Cheap Sound Absorbing Foam on the walls or ceiling is the best way to eliminate echoes, reverberations and reduce overall ambient noise in any room. Common sound problems are mainly caused by sound waves reflected from hard surfaces. Therefore, strategically placed acoustic panels at your known reflection points will not only effectively clean up the sound in a room, but the right amount of panels will eliminate all echoes and noise problems

Sound panels are used to eliminate reverberation and echoes in any room. They provide excellent sound absorption in all high and mid frequencies. Placing an acoustic panel at the first reflection point in the listening room will greatly enhance the overall sound. This is because it stops the sound waves from bouncing backwards and for the fourth time, resulting in better stereo imaging and greater depth of soundstage.

Open cell rubber foam sound-absorption foam

Glass wool Sound Absorbing Foam, also known as glass wool, is made from glass fibers. The glass is heated to a very high temperature until it melts and is then quickly spun into wool. These Glass wool Sound Absorbing Foam are then bonded together and used as an insulating material. The glass wool create pockets of air, which act as a barrier against heat loss, as air is a poor conductor of heat.

Glass wool Sound Absorbing Foam can be used in wool and rolls, loosely filled insulation and as a result of the fluffy wool crossing each other and having a large number of small holes, Glass wool Sound Absorbing Foam are based on the theory that perforated materials absorb sound. Glass wool Sound Absorbing Foam have a large number of small interconnected holes inside the material, through which sound waves can penetrate deep into the material and convert the sound energy into heat by friction with the material. It is a perforated sound-absorbing material and is typically a perforated sound-absorbing material with good sound absorption properties.

Centrifugal glass wool can be made into wall panels, ceiling panels and space absorbers, etc., absorbing a large amount of sound energy in the room and reducing reverberation time and indoor noise. When there is a layer of air behind the glass wool board, the sound absorption effect is similar to that of a glass wool board of the same thickness without an air layer. In particular, the sound absorption of low and medium-frequency sound signals will be much better than with a hard bottom surface with material attached.

The sound absorption coefficient increases with the thickness of the air layer. By stacking glass wool of different volume weight values and gradually increasing the total volume weight, a better sound absorption effect can be achieved. At the same time the coefficient of absorption gradually increases with increasing frequency, which means that the absorption of low-frequency sound signals is not as good as the absorption of high-frequency sound signals.

If you know what an acoustic panel is, the next thing to learn is how it actually works and what the material is.

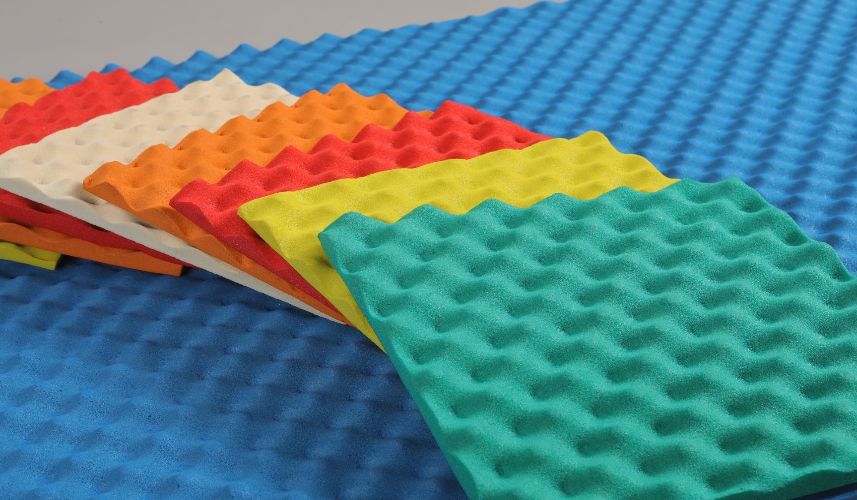

Ideally, each acoustic foam is made from polyurethane foam, such as polyether or polyester and extruded melamine foam. These are available in different sizes, colors and shapes and are cut into different tile-like panels.

A few acoustic foam panels are made of glass fibre, which has the ability to rub against sound waves and dissipate more of the sound vibrations into heat.

As mentioned earlier, the power of sound waves depends on the amplitude of the sound energy and acoustic foam panels help to minimise this, which is why they are mainly used in places such as churches, halls and studios to improve sound quality and minimise echoes.

Acoustic foam panels have different properties to handle sound energy, as flat surfaces are less able to absorb sound waves than foam panels with a pyramidal or eggshell shape.

As the sound energy may lie between the low-high frequency range, it may also be bass that cannot be captured by any acoustic panel, which is why there are different acoustic panels on the market.

Flat acoustic foam panels

Egg-shell acoustic foam panels

Pyramid acoustic foam panels

Wedge-shaped acoustic foam panels

Mesh foam panels

Corner bass trap foam panels

Each acoustic foam panel has its own importance and ability to reduce sound waves.

Which acoustic foam should I choose? -Contact Us

Fire resistant, durable, environmentally friendly, long fibres, no residual balls, not easy to produce dust, good for keeping the construction environment clean and good for the health of the construction workers. Good sound absorption, no sinking.

R-value

When comparing the two, glass wool has an R-value of approximately 2.2-2.7, which means that it is moderately effective in preventing heat loss through conduction.

Sustainability

If you are looking for the most sustainable option, glass wool is often made up of up to 50% recycled material. With increasing concern for environmental impact and sustainability, this is becoming increasingly important when choosing the right insulation material.

Sound insulation/acoustic insulation

When it comes to sound insulation, mineral wool is often the first choice for noisy areas. This is because it is cheaper and denser than glass wool, so much less sound can pass through the insulation.

Easy to install

If you are considering installing your own insulation, mineral wool is considered easier to handle. Although heavier than glass wool, mineral wool is easier to cut, move and install in place. On the other hand, glass wool is lame, which makes it difficult to adapt to the requirements.

makes it difficult to fit into the required space.

Potential savings

Reduced material costs: lower material thicknesses are required to achieve Class C and D compliance.

Reduced labour costs: reduced mass layer and cladding thickness for easier handling and installation.

Lighter weight on the pipe: lower density of mineral wool combined with reduced mass layer and cladding thickness.

All our potential customers have access to our free acoustic analysis as well as professional advice. Let your designers and architects contact us directly to find the right specification for any job. Rest assured that we will steer you in the right direction. Each of our soundproofing products will leave you in awe, and the installation accessories we sell with them create the perfect finishing touch. Take advantage of our experience by consulting your account manager throughout the ordering process. We can help you choose the perfect product to provide a unique solution to improve acoustics or control noise according to the needs of your area - and at no cost to you. If you are interested, contact us

Cheap Sound Absorbing Foam use

Cheap Sound Absorbing Foam are primarily used to modulate the sound in a room by reducing the echo, slap and reverberation caused by sound waves reflecting off hard surfaces and parallel walls, making the room sound more pleasing to the ear.

This article has detailed information about the use of acoustic foam rubber, you can directly click the link to view:https://www.huameiworld.com/news/does-sound-absorbing-rubber-foam-work.html

How much does soundproofing foam cost?

The price of foam used for sound treatment can vary. Size, thickness and design can all have an impact on cost. Our acoustic foams start at a budget friendly cost and increase in cost depending on the design and size you choose for your project.

How can I soundproof a wall cheaply?

Soundproofing walls with foam is a great way to get the job done on a budget. The use of sound insulation sheets, such as neoprene, are affordable and easy to implement in any location. These sheets are the most effective way to help prevent sound from passing through the walls.

How can I soundproof a room cheaply?

There are various options for soundproofing a room on a budget. Foam sheets, acoustic panels and corner blocks for attenuation are all cost-effective ways to complete your project. Remember that the best product for you will depend on the goals you are trying to achieve.

Custom sizing Cheap Glass wool Sound Absorbing Foam is what we do best. And you will be hard pressed to find them done anywhere else faster than by us. As long as the shapes are rectangles and squares. In some cases we can make other geometric shapes, but these are determined on a case-by-case basis. Contact one of our experts to see if we can bring your ideas to life. You can also order custom sizes online by clicking here

RELATED NEWS

Copyright © Huamei Energy-saving Technology Group Co., Ltd. All Rights Reserved | Sitemap | Privacy Policy

Insulation solutions LIST: Insulation solutions LIST