E-mail: marketing@hbhuamei.com

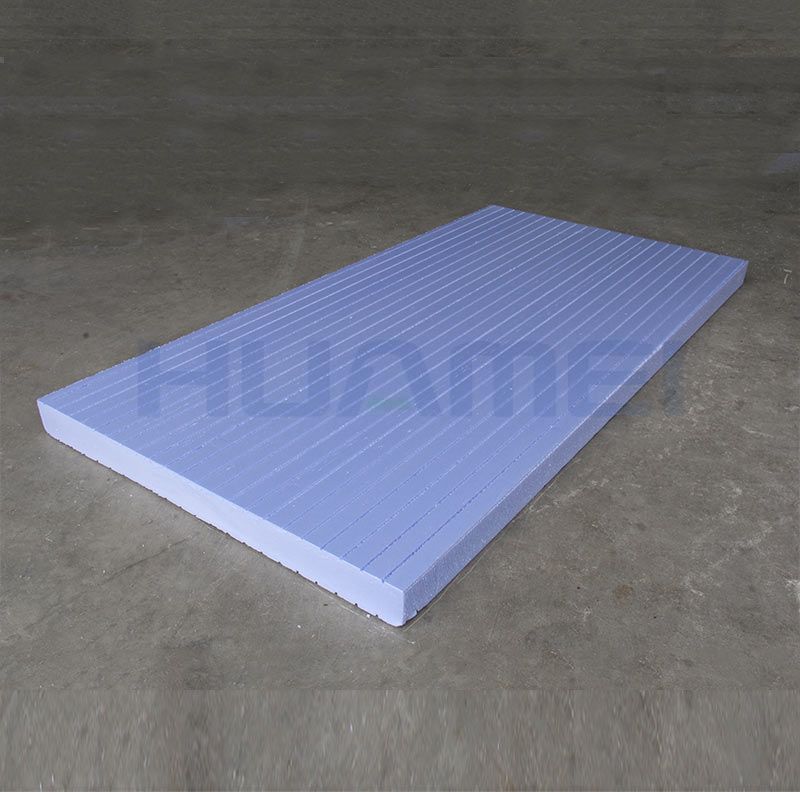

The XPS (extruded polystyrene) plate is a waterproof and highly compression-resistant plate.

The manufacturing process of extruded polystyrene (XPS) foam products is similar to that of expanded polystyrene (EPS) foam products.

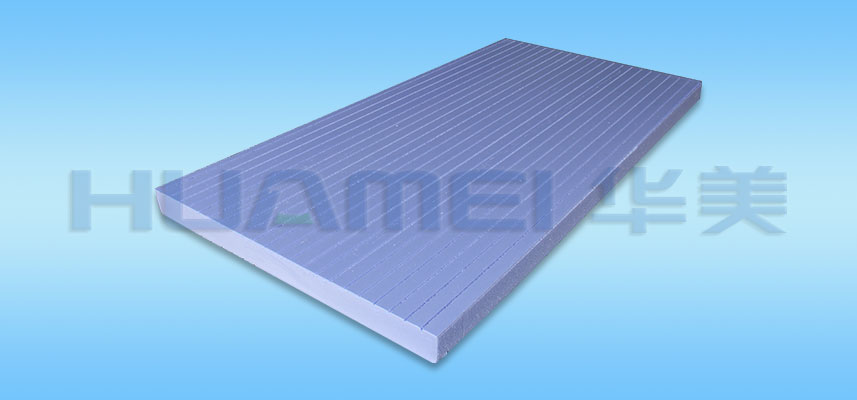

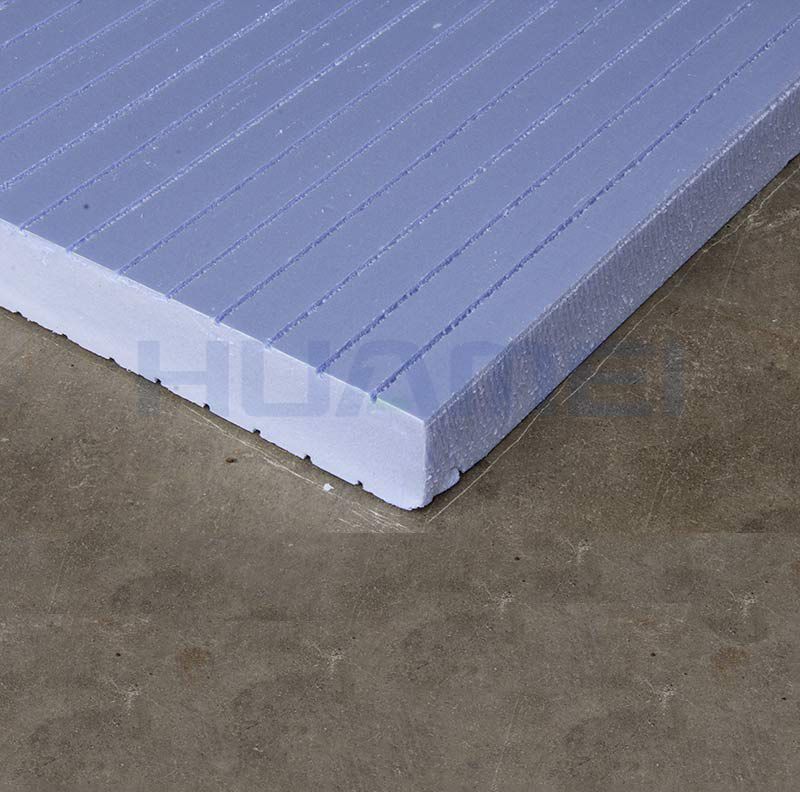

Double slotted XPS refers to the two longitudinal grooves on the surface of this XPS sheet. The double slotted design can effectively reduce the thermal bridge effect and improve the thermal insulation performance, and at the same time, it is easy to be spliced and fixed during installation, ensuring better sealing and overall structural stability. The double slotted structure also reduces the weight of the material, making construction easier.

Product Description

Huamei plastic extruded polystyrene sheets (XPS sheet)are serial products developed through special techniques according to the requirements of exterior wall insulation systems. For external insulation system for thin plaster exterior wall, there are pattern coating and stucco coating (coarse stucco and fine stucco) with both-side notches on the coating, which have the following features: easy and convenient operation, increased mortar adhesion area and enhanced adhesion strength, and all of these ensure sound stability, weather resistance and durability of the external insulation system for the exterior wall. Huamei plastic extruded plates are the best choice for exterior wall insulation systems.

XPS (extruded polystyrene) plate is a water resistant and highly compressive XPS plate.

Expanded polystyrene, or XPS insulation for short, is a closed cell insulation product that is commonly used in retrofit and new construction applications. Due to the manufacturing process, XPS insulation is usually only available in standard size square or rectangular panels. the brand of XPS rigid insulation is generally identified by the colour of the insulation

XPS (extruded polystyrene) panels offer a wide range of surface preparation materials, concrete floor grinding and polishing machines, decorative concrete and epoxy supplies for all industrial, commercial and residential flooring needs.

We offer a complete line of professional concrete and epoxy supplies, flooring equipment and construction materials for projects large and small.

Contact us now to get the best price

The manufacturing process of extruded polystyrene (XPS) foam sheet products is similar to that of expanded polystyrene (EPS) foam products. Both start with the same basic raw materials. But in the case of extruded polystyrene, polystyrene resin beads or pellets are fed into the extruder, where they are heated at a very high temperature until they melt. At this time, various additives are added to the molten mixture. One of these additives may be a colorant. Extruded Polystyrene Sheets are usually colored in multiple colors to identify them as a specific brand. For example, Owens Corning XPS foam sheet board is usually pink, while Dow XPS foam board is usually blue. Blowing agents are also added to expand the product after the extrusion process. Using carefully controlled heat and pressure, the plastic mixture is forced through a die (extrusion), then cooled and expanded into the desired shape. The resulting foam board is then trimmed to the final product size. Because the foam board is extruded, rather than poured into a mold like EPS foam board, the thickness of XPS products is limited.

XPS foam is considered to have a closed-cell structure, where the cells are closely packed together and there are no voids or spaces between them. The tightly packed unit of XPS foam helps prevent air and water from entering, making it more suitable for humid environments.

Strength and rigidity of Extruded Polystyrene Sheet

XPS foam has a tightly packed closed-cell structure, making it very strong and strong, making it an ideal choice for structural panels.

Compressive strength. XPS foam board is a rigid material with very high compressive strength. The product has a homogeneous closed cell cross-section with no voids, and each cell is completely closed by a polystyrene wall, giving it impressive strength. The product has a variety of compressive strengths to meet different applications. The manufacturing pressure of XPS foam board can reach 100 psi or higher.

Durability. Since XPS foam sheet board is a thermoplastic material, it will not rot or decompose over time. It can also resist microorganisms in the soil. Moreover, it is not attractive to rats and other pests as a food source. Its service life is up to 50 years.

Chemically inert. XPS foam sheet board is considered a fairly chemically inert material. It is resistant to most acids, alkalis and aqueous solutions of salts and alkalis. However, many organic solvents such as acetone, chlorinated solvents, and aromatic solvents can attack and dissolve foam.

Size and density. XPS foam boards can be manufactured with or without plastic finishes.

energy efficiency. XPS foam sheet board is an energy-saving building material. Buildings insulated with XPS foam panels save much more energy throughout their lifecycle than the energy used in the manufacturing process of the products.

Dimensional stability. XPS foam board will expand and warp significantly at higher temperatures.

Sustainability. When used as insulation for homes or buildings, XPS foam panels have been proven to reduce the energy required to maintain their heating and cooling, thereby reducing the consumption of our depleted natural resources. Moreover, since polystyrene resin is a thermoplastic material used to make XPS foam boards, the foam boards can be melted and reused to produce new XPS insulation materials. More importantly, this is the common practice today. According to the Extruded Polystyrene Foam Association, XPS manufacturing plants do not generate "scrap" or waste, because 100% of industrial waste XPS foam boards are recycled, decomposed into resin materials and reused in the XPS foam manufacturing process.

XPS plates foam is a rigid foam that provides a strong, lightweight and flexible insulation solution that resists water absorption, making it ideal for a variety of construction and commercial applications.

xps plates saves on machine, concrete and epoxy floor coatings!

Due to the way xps plates are manufactured, unlike other plates, they have closed pores. This means that water cannot enter its interior. When water gets inside the XPS plate, two things happen: the XPS plate stops working as a thermal insulator and, on the other hand, the cladding and exterior walls become wet and therefore dirty, harbouring fungus and various derived disease-like moisture.

xps plates is a highly resistant panel. It is so durable that it is also used for insulated flooring.

For all these reasons, we recommend using this type of XPS plate as a base on the ground floor of a building to protect against rain and bribery.

Excellent thermal comfort with xps plates

energy efficiency of xps plates

xps plates high resistance

xps plates is a rigid foam board, referred to as XPS. explore our product range below and if you need any help, please feel free to call or contact a member of our team via live chat. To find out more about products such as xps plates, please read our guide.

| Item | Unit | Specification | Test Method |

| CompressIve Strength | Kpa | ≥150 | GB/T 8813-1988 |

| Water Absorption 96h | %(V/V) | ≤1.0 | GB/T 8810-1988 |

| Coefficient (23℃±1℃)(RH50%±5%) | ng/(m•s▪pa) | ≤3.0 | QB/T 2411-1998 |

| Conductivity facto Average temperature 10℃ 25℃ | W/(m•k) | ≤0.028 ≤0.030 | GB/T 10294-1988 |

| Dimension stability 70℃±2℃,48h | % | ≤1.5 | GB/T 8811-1988 |

| Oxygen index | ≥26 | GB/T 8826-1988 |

| Item | Unit | Size |

| Length | mm | 1800,1200 |

| Width | mm | 600,900,1200 |

| Thick | mm | 20,25,30,40,50,60,70,80,90,100 |

XPS (Extruded Polystyrene) board is a waterproof and high compression board. With closed pores, thus requiring waterproofing, Huami offers extruded polystyrene (XPS) foam, a rigid foam that provides a strong, lightweight and flexible insulating solution that resists water absorption, making it a versatile Ideal for architectural and commercial applications. In addition to being impermeable to water, it is also a highly compressive sheet. It is very durable, so it is also used to insulate floors. On the first floor, the façade is often subject to various blows, such as children playing with a ball... As a solution, this type of slab combined with a vandal-resistant mesh is highly recommended to protect the cladding.

Expanded polystyrene, or XPS insulation for short, is a closed-cell insulation product commonly used in retrofit and new construction applications. Due to the manufacturing process, polystyrene board insulation is usually only available for standard-sized square or rectangular boards.

To learn more about products like the XPS insulation board, read our guide. If you need any assistance, please feel free to email us or reach a member of our team via live chat.

Reduce heating and cooling costs

Versatility

Does not support mold or mildew growth

environmentally friendly

No leakage

endurance

basic insulation;

Floor insulation on the ground;

Insulation of structural elements;

Industrial floor insulation;

parking lot insulation;

route isolation

The use of xps plates materials in commercial and residential buildings offers great flexibility, compatibility and thermal efficiency in all areas of the building envelope.

xps plates are suitable for a variety of applications - from wall and ceiling insulation, cold rooms and refrigeration, under concrete slabs (i.e. car parks) and even for architectural modelling or hobby modelling.

The permeability rating of xps plates is approximately 1, making them semi-permeable. Thicker XPS is stronger and has a lower perm rating, but it is still considered a vapour barrier, not a vapour barrier.

The xps plates likewise improve with lower temperatures. It has a nominal R-value of 5 per inch. This is the bulk of the foam you see used for exterior sheathing. Over time, extruded polystyrene foam will release gases and lose some of its insulating properties - especially below grade and when tested in practical applications.

Both the pink and blue xps plates materials are rigid insulation boards made from extruded polystyrene. The two products are similar in terms of chemical composition, manufacturing process and insulation capacity, the main difference between them is that they are manufactured by two different companies.

Extruded polystyrene foam is a rigid foam board and is referred to as XPS. Explore HUAMEI range of XPS plate and feel free to contacta member of our team on +86 22 2626 2121 or via Live Chat if you need any help. To know more about products like XPS insulation board Read Our Guide above.

RELATED NEWS

Copyright © Huamei Energy-saving Technology Group Co., Ltd. All Rights Reserved | Sitemap | Privacy Policy

Insulation solutions LIST: Insulation solutions LIST