E-mail: marketing@hbhuamei.com

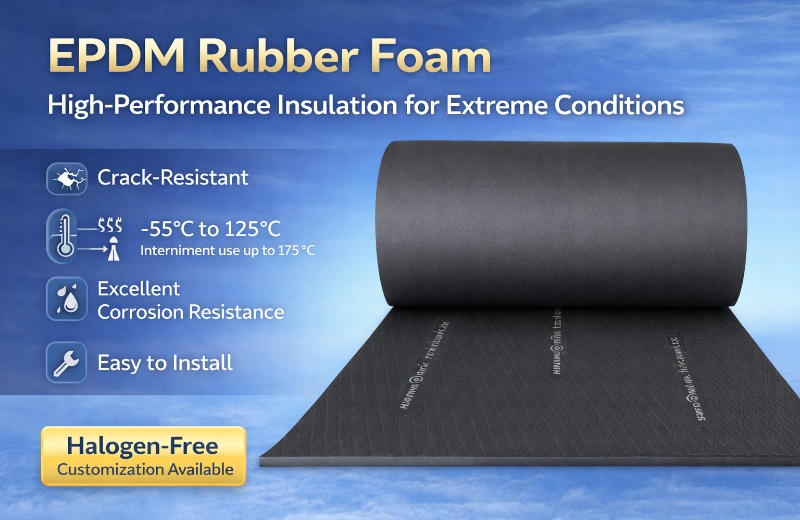

In industrial, construction, and energy-related applications, materials are increasingly required to perform reliably under extreme conditions—from severe temperature fluctuations and high humidity to prolonged UV exposure and aggressive chemical environments. Against this backdrop, EPDM rubber foam has emerged as a preferred insulation and sealing material, widely recognized for its stability, durability, and long-term performance.

One of the primary reasons EPDM rubber foam is used under extreme conditions lies in its exceptional temperature resistance. EPDM-based foam materials typically operate reliably across a wide range, from –40°C to +120°C, with certain formulations tolerating even higher short-term temperatures.

This thermal stability makes EPDM rubber foam particularly suitable for:

HVAC and refrigeration systems

Industrial piping and duct insulation

Outdoor mechanical and electrical installations

Unlike conventional rubber or plastic foams, EPDM rubber foam maintains flexibility and mechanical integrity even after repeated thermal cycling.

Extreme outdoor environments pose a serious challenge to insulation materials. Continuous exposure to sunlight, ozone, rain, and oxygen can cause cracking, embrittlement, and performance loss.

EPDM rubber foam is inherently UV- and ozone-resistant, thanks to its saturated polymer backbone. This allows it to:

Retain elasticity over long service periods

Prevent surface degradation and cracking

Reduce maintenance and replacement frequency

For rooftop systems, outdoor pipelines, and exposed equipment, EPDM rubber foam provides a clear advantage over traditional insulation materials.

Moisture ingress is a major cause of insulation failure, especially in extreme climates. EPDM rubber foam features a closed-cell structure, which significantly limits water absorption and vapor permeability.

Key benefits include:

Stable thermal insulation performance in humid environments

Reduced risk of condensation and corrosion under insulation (CUI)

Improved energy efficiency over the product lifecycle

This makes EPDM rubber foam an ideal solution for marine environments, coastal regions, and industrial plants with high ambient humidity.

Extreme conditions often involve exposure to chemicals, oils, and cleaning agents. EPDM rubber foam exhibits excellent resistance to many acids, alkalis, and polar solvents, allowing it to maintain structural stability in demanding industrial settings.

Typical application scenarios include:

Chemical processing facilities

Power generation plants

Manufacturing environments with aggressive cleaning regimes

Its chemical resilience contributes to safer operation and longer service life.

While initial material selection often focuses on performance, lifecycle cost is equally critical. EPDM rubber foam is valued for its long service life and low degradation rate, even under harsh operating conditions.

From an economic standpoint, this translates into:

Reduced replacement and downtime costs

Lower maintenance requirements

Consistent insulation performance over time

For projects designed to operate under extreme conditions, these long-term benefits are decisive.

As industries continue to push operational boundaries, material reliability under extreme conditions has become non-negotiable. With its wide temperature tolerance, superior weather resistance, moisture stability, and chemical durability, EPDM rubber foam stands out as a technically sound and economically efficient solution.

For engineers, contractors, and project owners seeking dependable performance in the harshest environments, EPDM rubber foam is not just an option—it is a strategic material choice.

Copyright © Huamei Energy-saving Technology Group Co., Ltd. All Rights Reserved | Sitemap | Privacy Policy

Insulation solutions LIST: Insulation solutions LIST