E-mail: marketing@hbhuamei.com

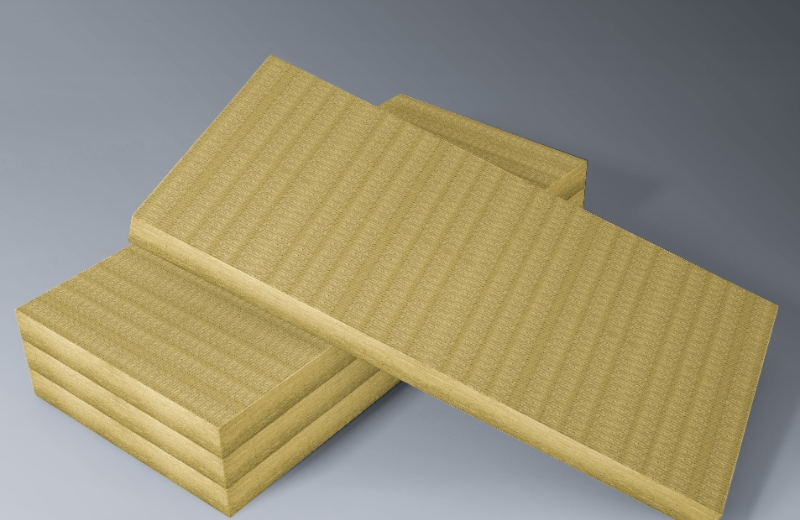

As moisture control and indoor air quality become central concerns in modern construction, rockwool insulation mold-resistant performance is gaining increased attention from architects, contractors, and building owners worldwide. Unlike many conventional insulation materials, rockwool Insulation Mold-Resistan properties are rooted in its inorganic composition and advanced manufacturing process, making it a reliable solution for long-term building protection.

Mold growth is a common challenge in buildings exposed to humidity, condensation, or water intrusion. Once mold develops, it can compromise structural integrity, reduce insulation efficiency, and negatively affect occupant health. In this context, rockwool Insulation Mold-Resistan solutions are increasingly specified in residential, commercial, and industrial projects where durability and hygiene are critical.

Compared with organic insulation materials, mold resistant rockwool insulation provides a fundamentally different approach to moisture and microbial control.

One of the key reasons rockwool insulation mold-resistant characteristics stand out lies in its raw materials. Rockwool insulation is produced from natural volcanic rock, such as basalt, which is melted and spun into fibers at extremely high temperatures.

Because rockwool Insulation Mold-Resistan structures contain no organic nutrients, mold spores have nothing to feed on. This inorganic nature is a decisive factor that differentiates rockwool insulation mold-resistant systems from fiber-based or foam insulation products that may support microbial growth under damp conditions.

Another critical factor behind rockwool Insulation Mold-Resistan performance is its hydrophobic fiber structure. While rockwool insulation is vapor-permeable, it is engineered to repel liquid water. This balance allows moisture vapor to pass through while preventing water absorption.

As a result, rockwool insulation mold-resistant behavior helps maintain a dry internal environment, reducing the likelihood of condensation buildup. This feature is especially valuable in wall cavities, roofs, and HVAC applications where temperature differences often create moisture risks.

Unlike closed-cell insulation materials, rockwool Insulation Mold-Resistan products support breathability. When exposed to temporary moisture, rockwool fibers allow water vapor to evaporate efficiently rather than becoming trapped within the insulation layer.

This drying capability reinforces the mold resistant rockwool insulation advantage, ensuring that even in high-humidity climates, the insulation can recover its thermal performance without fostering mold growth.

Beyond moisture control, rockwool insulation mold-resistant solutions also offer inherent fire resistance. Manufactured at temperatures exceeding 1,400°C, rockwool insulation does not burn, melt, or emit toxic smoke.

This dual benefit strengthens the overall value of rockwool Insulation Mold-Resistan materials, making them suitable for applications where both fire safety and mold prevention are required, such as hospitals, schools, data centers, and high-rise buildings.

Durability is another defining feature of rockwool Insulation Mold-Resistan systems. Over time, some insulation materials degrade, shrink, or lose performance when exposed to moisture cycles. Rockwool insulation, however, maintains its dimensional stability and fiber structure even under fluctuating temperature and humidity conditions.

This long-term stability ensures that rockwool insulation mold-resistant performance remains consistent throughout the building’s lifecycle, reducing maintenance costs and improving overall sustainability.

The demand for rockwool Insulation Mold-Resistan solutions is expanding across multiple sectors:

Exterior wall systems exposed to rain and humidity

Roof insulation in flat and low-slope roofs

Basement and foundation insulation

Industrial facilities with high moisture loads

Public buildings requiring strict indoor air quality standards

In each of these scenarios, mold resistant rockwool insulation provides reliable protection against moisture-related risks.

As green building certifications place increasing emphasis on occupant health, rockwool insulation mold-resistant materials align well with sustainability goals. Their resistance to mold growth supports healthier indoor environments without relying on chemical additives or biocides.

This natural approach further reinforces why rockwool Insulation Mold-Resistan technology is favored in environmentally responsible construction projects.

In today’s construction landscape, mold prevention is no longer optional—it is essential. Through its inorganic composition, hydrophobic yet breathable structure, and long-term stability, rockwool insulation mold-resistant performance addresses mold risks at their source.

For projects seeking durable, safe, and health-conscious insulation solutions, rockwool Insulation Mold-Resistan products continue to set a high standard, delivering reliable protection against moisture and mold while supporting modern building performance requirements.

Copyright © Huamei Energy-saving Technology Group Co., Ltd. All Rights Reserved | Sitemap | Privacy Policy

Insulation solutions LIST: Insulation solutions LIST