E-mail: marketing@hbhuamei.com

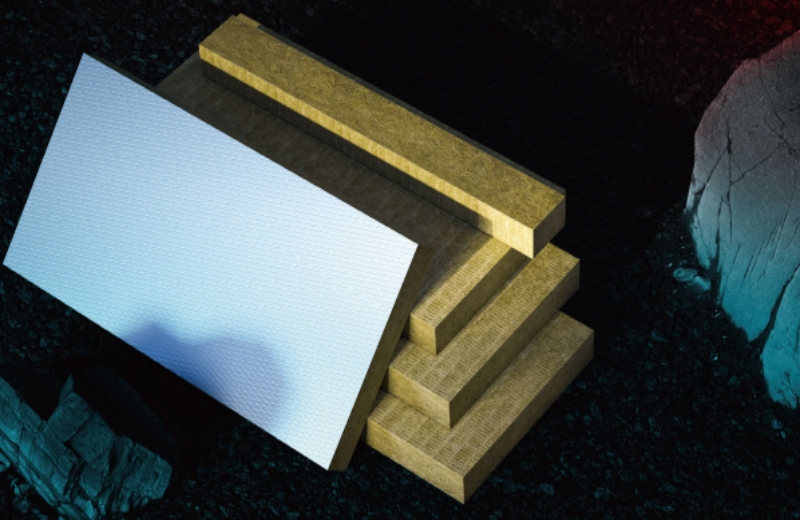

Rock wool insulation, also known as mineral wool insulation, is a high-performance thermal and acoustic insulation material widely used in construction, industrial, and infrastructure projects. Thanks to its excellent fire resistance, thermal stability, and durability, rock wool insulation has become a preferred choice for modern buildings that prioritize safety, energy efficiency, and long-term performance.

This page provides a comprehensive introduction to what rock wool insulation is, how it is structured, and the key benefits that make it one of the most reliable insulation materials on the global market.

Rock wool insulation is a fibrous insulation material manufactured from natural volcanic rock, typically basalt, combined with recycled slag from the steel industry. These raw materials are melted at extremely high temperatures and then spun into fine fibers, creating a dense, wool-like structure.

Because of this inorganic composition, rock wool insulation is non-combustible, dimensionally stable, and resistant to moisture, mold, and aging. It is commonly used in building envelopes, industrial insulation systems, fire protection assemblies, and acoustic applications.

Rock wool insulation is often classified under the broader category of mineral wool insulation, alongside glass wool. However, rock wool offers superior fire resistance and mechanical strength compared to many alternative insulation materials.

The performance of rock wool insulation is directly related to its unique fiber structure and material composition.

Rock wool insulation is primarily made from:

• Basalt and other natural volcanic rocks

• Recycled industrial slag

• Minimal organic binders to stabilize the fiber matrix

This combination allows rock wool insulation to maintain consistent performance even under extreme temperature conditions.

During production, molten rock is spun into millions of intertwined fibers. These fibers are randomly oriented, forming a three-dimensional network that traps air effectively. This structure is the foundation of rock wool insulation’s thermal and acoustic performance.

The dense fiber network also contributes to high compressive strength, making rock wool insulation suitable for applications where mechanical stability is required.

Rock wool insulation is valued for a balanced combination of thermal, fire, acoustic, and environmental properties.

Rock wool insulation has a low thermal conductivity, which helps reduce heat transfer through walls, roofs, and industrial equipment. By limiting heat loss in winter and heat gain in summer, rock wool insulation contributes significantly to building energy efficiency and indoor comfort.

One of the most important properties of rock wool insulation is its exceptional fire resistance. Rock wool insulation is non-combustible and typically classified as A1 fire-rated material under international standards. It can withstand extremely high temperatures without melting or releasing toxic smoke, making it a critical component in fire protection systems.

The open and porous fiber structure of rock wool insulation effectively absorbs sound waves. This makes rock wool insulation an ideal solution for noise reduction in residential buildings, commercial spaces, industrial plants, and HVAC systems.

Because rock wool insulation is inorganic, it does not provide a nutrient source for mold or bacteria. Its water-repellent properties help maintain insulation performance even in humid environments, reducing the risk of long-term degradation.

Rock wool insulation does not shrink, warp, or settle over time. Its dimensional stability ensures consistent insulation performance throughout the entire service life of a building or industrial installation.

The combination of structure and material properties gives rock wool insulation several advantages over other insulation materials.

Thanks to its non-combustible nature, rock wool insulation significantly improves fire safety in buildings. It helps slow fire spread and provides valuable time for evacuation and emergency response.

By minimizing thermal bridging and heat loss, rock wool insulation supports lower energy consumption and more stable indoor temperatures, contributing to long-term operational savings.

Rock wool insulation improves acoustic comfort by reducing airborne and impact noise, making it suitable for residential, commercial, and industrial soundproofing applications.

Rock wool insulation is manufactured using abundant natural resources and recycled materials. Its long lifespan and recyclability make it a responsible insulation solution aligned with sustainable construction practices.

Due to its reliable performance across multiple criteria, rock wool insulation is widely specified by architects, engineers, and contractors worldwide. It is suitable for applications ranging from exterior wall systems and roofing to industrial equipment insulation and fire-rated assemblies.

As building regulations continue to emphasize fire safety, energy efficiency, and acoustic comfort, rock wool insulation remains a future-proof solution for both new construction and renovation projects.

For detailed product specifications, available formats, and application-specific solutions, please refer to our Rock Wool product page.

Copyright © Huamei Energy-saving Technology Group Co., Ltd. All Rights Reserved | Sitemap | Privacy Policy

Insulation solutions LIST: Insulation solutions LIST