E-mail: marketing@hbhuamei.com

As global construction trends move rapidly toward sustainability and energy efficiency, Rock Wool Insulation has emerged as one of the fastest-growing materials in the insulation industry. In 2025, experts predict that the global Rock Wool Insulation market will exceed USD 20 billion, driven by stricter energy codes, green building standards, and the increasing focus on fire safety.

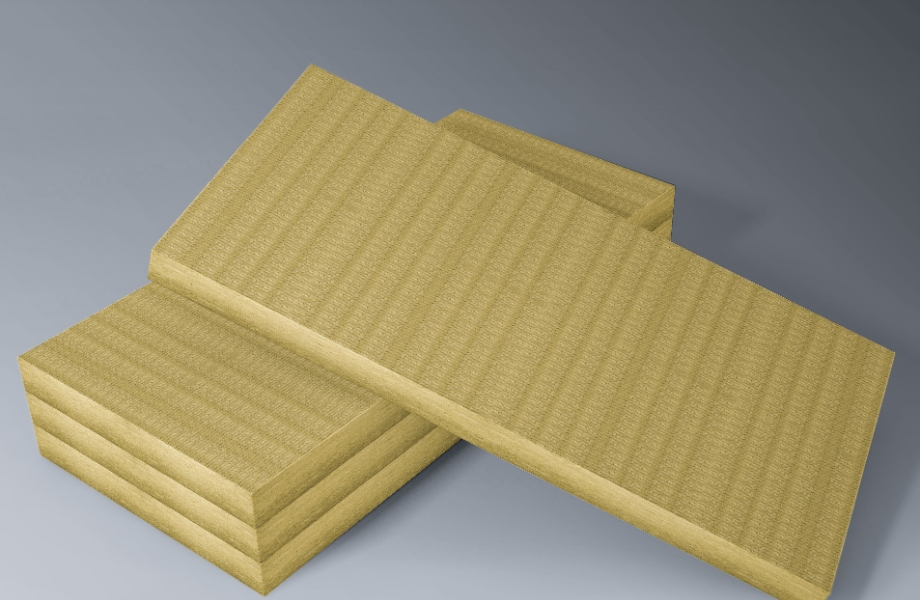

Compared with traditional materials, Rock Wool Insulation offers unmatched thermal and acoustic performance. Made from natural basalt rock, Rock Wool Insulation delivers superior energy efficiency, helping buildings maintain stable indoor temperatures while reducing heating and cooling costs. Additionally, the non-combustible nature of Rock Wool Insulation makes it a preferred choice for architects and engineers who prioritize safety and fire protection in high-rise and industrial structures.

In recent years, governments worldwide have tightened fire safety codes. As a result, Rock Wool Insulation has become the go-to solution for fire-resistant walls, roofs, and facades. Its ability to withstand temperatures exceeding 1000°C further underscores its reliability in extreme environments.

The global green building movement is another major factor fueling the demand for Rock Wool Insulation. With certifications such as LEED and BREEAM emphasizing energy performance, Rock Wool Insulation enables builders to meet sustainability goals without compromising structural performance. Moreover, Rock Wool Insulation is fully recyclable and produced from abundant natural materials, aligning with circular economy principles.

Manufacturers are also innovating rapidly. New generations of Rock Wool Insulation now feature enhanced vapor control, water repellency, and improved sound absorption, making them suitable for residential, commercial, and industrial applications alike. Whether in data centers, hospitals, or schools, Rock Wool Insulation continues to play a pivotal role in improving comfort and reducing carbon footprints.

According to industry analysts, Asia-Pacific and Europe remain the two largest markets for Rock Wool Insulation, with rapid expansion in North America driven by retrofit projects and strict energy-efficiency legislation. Major construction projects, from high-speed rail stations to industrial plants, are increasingly specifying Rock Wool Insulation as the standard thermal barrier material.

In industrial applications, Rock Wool Insulation is used extensively in power plants, petrochemical facilities, and shipbuilding. Its high dimensional stability and durability make Rock Wool Insulation the material of choice where long-term thermal performance and fire protection are essential.

Despite strong market momentum, challenges remain. The production process of Rock Wool Insulation requires significant energy input, and manufacturers are actively investing in cleaner technologies to reduce emissions. With growing consumer awareness and global net-zero targets, the industry is expected to shift toward greener manufacturing processes for Rock Wool Insulation over the next decade.

Experts agree that Rock Wool Insulation will continue to lead the market as a sustainable, high-performance, and safety-driven insulation solution. Its combination of thermal efficiency, acoustic control, fire resistance, and recyclability positions Rock Wool Insulation as a cornerstone of the future built environment.

From skyscrapers to energy-efficient homes, Rock Wool Insulation is no longer just an option — it’s a standard for modern, sustainable construction. As innovation continues, the versatility and environmental advantages of Rock Wool Insulation are setting new benchmarks for insulation technology worldwide.

Copyright © Huamei Energy-saving Technology Group Co., Ltd. All Rights Reserved | Sitemap | Privacy Policy

Insulation solutions LIST: Insulation solutions LIST