E-mail: marketing@hbhuamei.com

The selection of proper insulation is not always an easy task, in particular when it is necessary to work within cold temperatures, moisture, or sensitive systems. These two materials Cryogenic Rubber Foam and glass wool are some of the most frequently utilized materials within the industry.

While both offer good thermal performance, they are built differently and serve different needs. This article discusses the key differences and benefits of Cryogenic Rubber Foam and glass wool so that you can choose the right one for your project.

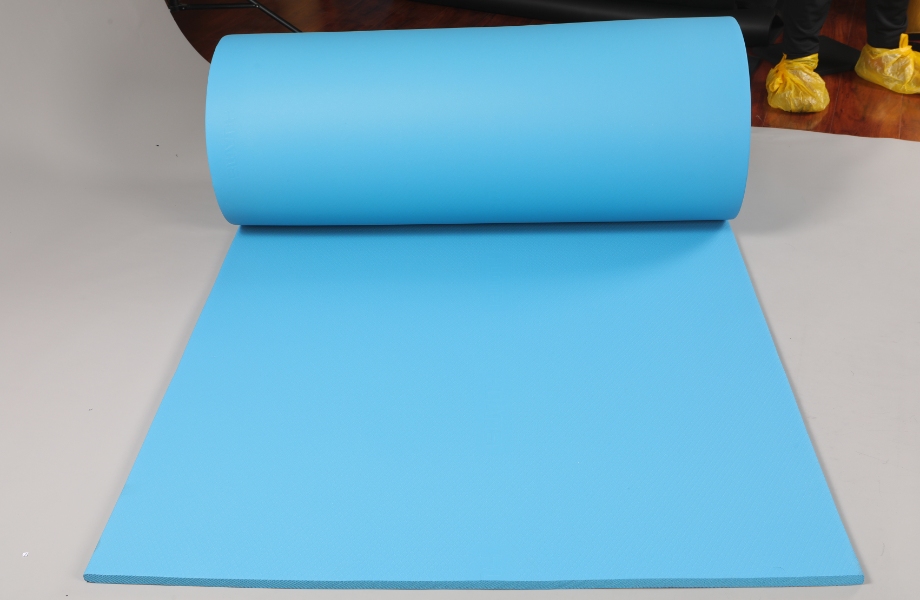

Cryogenic Rubber Foam is a soft closed-cell insulation material that can work at extremely low temperatures. It finds application in the piping network of LNG, supplying medical oxygen, cold storage, and cryogenic transport of gases. The foam traps air in tiny cells and blocks heat and moisture, making it great for long-term cold applications.

Glass wool, also known as fiberglass insulation, is made from spun glass fibers. It is of low weight and soft. It is commonly utilized on walls, ceilings, ducts or the overall HVAC. Glass wool performs well in dry indoor places and provides good soundproofing and fire resistance capability.

Let’s look at the core differences between Cryogenic Rubber Foam and glass wool:

Feature | Cryogenic Rubber Foam | Glass Wool |

Structure | Closed-cell foam | Loose or woven glass fibers |

Moisture Resistance | Very high, water vapor resistant | Low, absorbs moisture easily |

Flexibility | Highly flexible | Not very flexible |

Thermal Conductivity | Very low, Ideal for freezing temps | Moderate, Better for room temps |

Dust and Fiber Safety | No dust or irritation | Can irritate skin and lungs |

Noise Reduction | Moderate | Very good |

Fire Resistance | Good fire-resistance | Excellent |

Installation | Easy to bend and fit | Needs more handling care |

Use Cryogenic Rubber Foam When:

● You need long-term insulation in freezing environments

● There’s a risk of high humidity or condensation

● You want a material that’s easy to install and wrap around curves or bends

● Your project needs low maintenance over time

Use Glass Wool When:

● You need thermal and sound insulation in dry indoor spaces

● Your system stays above freezing

● Cost and weight are key concerns

● You want strong fire resistance in wall or ceiling cavities

Let’s zoom in on why Cryogenic Rubber Foam is trusted in cold, high-moisture environments:

● Blocks moisture: Its closed-cell structure keeps water and vapor out

● Stays flexible: It bends easily, making it perfect for complex piping systems

● Lasts long: It doesn’t sag, settle, or break down easily over time

● Safe to handle: No glass fibers, no skin or breathing issues

● Performs in extreme cold: It holds up even in cryogenic temps without cracking

For businesses working with LNG, refrigerated gases, or medical systems, this type of insulation checks all the boxes.

Glass wool is suitable for a lot of tight building jobs. Here’s why it is popular:

● Walls and air ducts: It can fit into tight areas and this prevents heat from being carried to them.

● Reduces noise: It is so absorbent regarding sound and is made of soft and fluffy fibers.

● Will not burn: It can be used where fire precaution regulations are of importance.

● Light and low-cost: It’s easy to carry, move and install, especially in dry places.

Just remember, in wet or freezing conditions, glass wool doesn’t work as well.

That depends on your project needs. Cryogenic Rubber Foam is the superior choice in case your system requires dealing with very low temperatures, moisture, or long operating hours. It provides you longevity, moisture-resistance and reduced long-term expenditure. If your project is indoors, dry, and more focused on sound or fire performance, glass wool may be enough.

Still unsure? Let’s make it simple:

● Go with rubber foam for pipes, cold rooms, cryogenic tanks, or LNG setups.

● Go with glass wool for walls, HVAC ducts, office ceilings, or noise control.

Huamei has years of experience in assisting businesses in finding the proper insulation solution. Do you prefer Cryogenic Rubber Foam, glass wool or a combination? All our products are tried and tested and come with the support and service that you would expect.

We have 10 factories, and exports to 40+ countries with several decades of experience allow us to know what works and how to provide it. We help you reduce energy loss, protect your systems, and meet project deadlines with ease. Want help choosing the right product? Need bulk supply or specs? Just visit us we’re here to help.

Both Cryogenic Rubber Foam and glass wool have their strengths. The key is knowing when and where to use them. Rubber foam is the best option when it comes to wet, cool or outside systems. Glass wool is most desirable when used to provide fire and sound insulation in dry and interior areas.

It doesn't matter what you pick, but it does need to be suited to your project to your goals and surroundings. Still in doubt? Reach out to Huamei, a supplier you can trust.

Copyright © Huamei Energy-saving Technology Group Co., Ltd. All Rights Reserved | Sitemap | Privacy Policy

Insulation solutions LIST: Insulation solutions LIST