E-mail: marketing@hbhuamei.com

OUR FACTORY

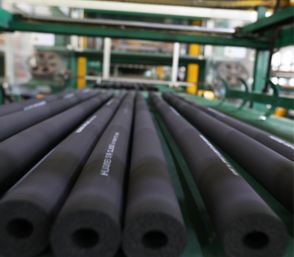

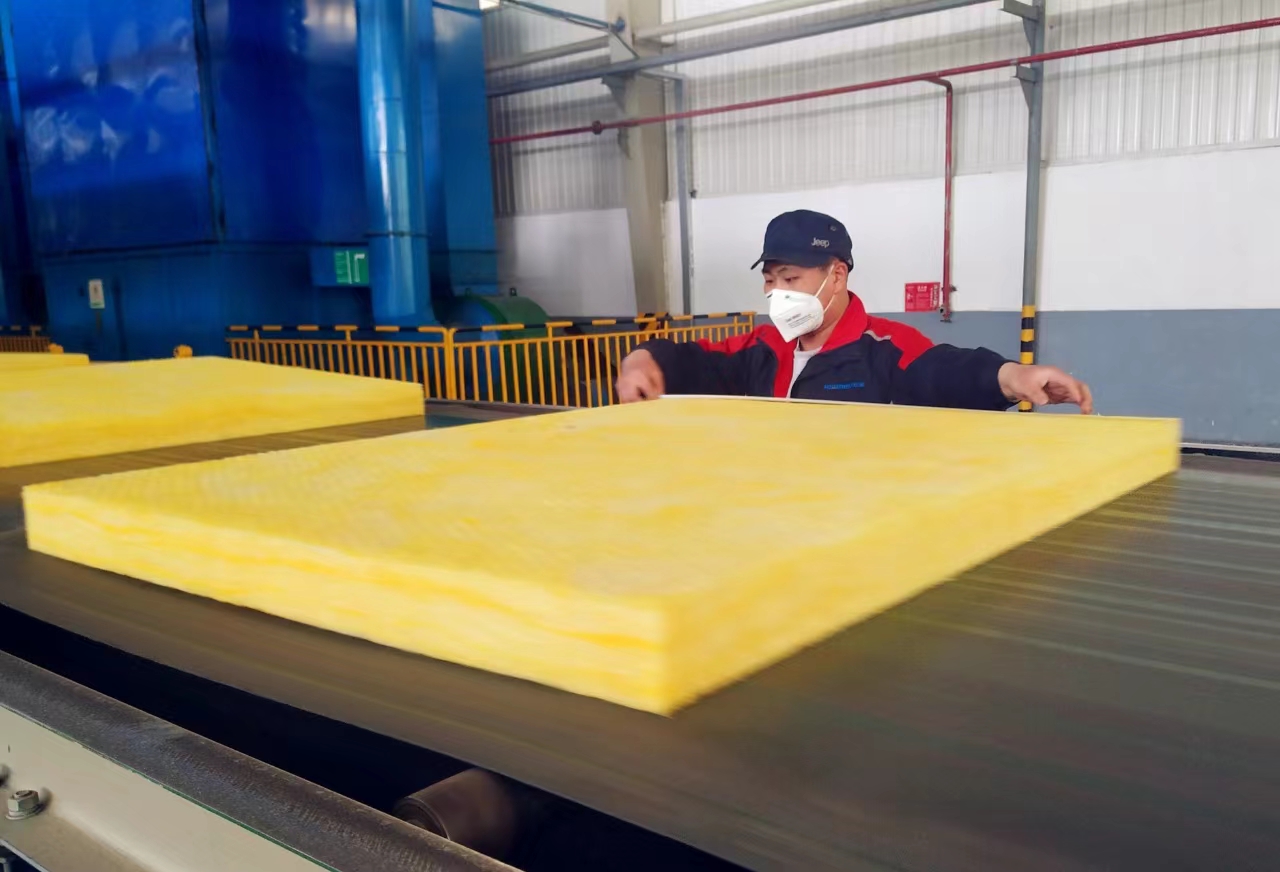

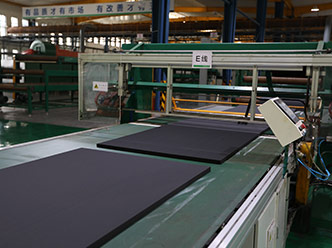

The headquarters located in the heartland of Beijing-Tianjin-Hebei region and the Bohai Sea economic circle,Huamei Energy-saving Technology Group is a large conglomerate incorporating research and development, production and sales.Huamei group consists of 8 companies, has 10 industrial parks,and has production bases in Hebei,Sichuan,Guangdong,Jiangxi and guangxi,main business of rubber foam insulation material, centrifugal glass wool, rock wool,and extruded polystyrene insulation board (XPS), and other thermal insulation products. The annual production capacity of rubber foam materials is 1.4 million cubic meters, and the annual production capacity of glass wool is over 400000 tons.

8+

Branch Office

10+

Industrial Park

1.4+

Million Cubic Meters

Annual production capacity of rubber and plastic materials

400000+

Tons

Annual production capacity of glass wool

FIRST-CLASS PRODUCTION TECHNOLOGY AND INDUSTRIAL ADVANTAGES

In the world advocating energy conservation and environmental protection nowadays, Huamei Energy-saving Technology Group is unique and unparalleled in thermal insulation industry with its top-notch production technology and industrial advantages. Excellent quality, perfect service, convenient transportation, prompt and timely logistics system enable “Huamei” brand products to cover all provinces, municipalities and autonomous regions, widely used in Project of Beijing Olympic National Stadium (Bird’s Nest),Terminal 3 of the Capital International Airport,The National Theatre,Beijing Daxing International Airport,Beijing Municipal Administrative Center,Beijing-Tianjin High Speed Railway,the World Exposition in Shanghai,Xiong'an citizen Service Center,Xiong'an railway station and some other famous projects, and to be exported to Europe, Africa, Russia, Australia, Japan, Korea and Southeast Asia and other countries.

OUR CERTIFICATION

“Huamei” took the lead in obtaining the titles of “Double well-known trademark of China”, “Asian famous brand”, “Asia's top ten innovative brands” in the same industry. In the same industry in China, Huamei Group also took the lead in obtaining the qualifications and certifications of flame-retardant product mark, three-star green building materials evaluation marks, building insulation material fire safety performance, fire safety and environmental building material marks, China Classification Society certification,Ten Rings Product. And relevant products have passed product certification of American FM, green guard gold, Korean KS, RoHS and EU’s CE , as well as the tests of British BS 476: Part 7 & BS476: Part 6 and American ASTM E84,Huamei group is the vice president unit of China thermal insulation and energy saving materials association and has provincial R&D platforms such as Hebei Key Laboratory of thermal insulation materials and Hebei Institute of thermal insulation industry technology, and participated in the drafting of multiple national standard, such as GB/T 17794-2008、GB/T 13350-2008、GB/T17795-2008、GB8624-2012、GB∕T13350-2017、GB∕T 35608-2017、GB/T25975-2018、GB/T10801.2-2018、GB/T 17795-2019、GB/T17794-2021、JC/T2495-2018.These all presents the industry influence of Huamei group and the excellent technical performance of Huamei products. And now, Huamei has become a landmark enterprise in China's thermal insulation and energy-saving material industry.

OUR VALUES

Huamei Energy-saving Technology Group has been practicing the core values of “humanism, respect, service, innovation, lean”.With the mission of "Innovation and intelligent manufacturing energy-saving products, ingenuity shaping a world brand.", Huamei Group is focusing on creating high-quality eco-friendly and energy-conserving products through its professional production technology, precise management, and excellent equipment, taking green energy-saving technology as core competitiveness, and made our unremitting efforts to become a global leading enterprise committed to a better life for mankind.

Technological Innovation Advantage

The company focuses on technological innovation and technological progress, has a professional research and development team, gives full play to the spirit of craftsmanship, and ploughs into the application of green thermal insulation and energy-saving science and technology. We cooperate with Beihua Institute of Aerospace Industry, Tianjin University, Nankai University, NGSI and other colleges and universities and scientific research institutes, and carry out product research and development activities relying on the technology research and development platforms such as Hebei Provincial Enterprise Technology Center, Hebei Provincial Key Laboratory of Insulation and Thermal Insulation Materials, Hebei Provincial Insulation and Thermal Insulation Materials Industry Research Institute and so on, and have achieved fruitful results. In the past three years, invested R & D funds of 95 million yuan, developed microporous foamed rubber, high flame retardant low smoke density rubber, high temperature rubber, rubber, ultra-low temperature rubber, no monomersulfur rubber, heat sealing foil veneer glass wool, ultra-long ultra-fine fiber glass wool, environmental protection glass wool, agricultural cotton, and other core technologies 28, the development of new products, new varieties of 35, participated in the drafting of the national standards of 10, access to the invention patents, 13, 83 utility models. 83 utility models. 2 Hebei Province Science and Technology Achievement Certificates.

Infrastructure advantages

Huamei attaches importance to infrastructure construction and management work, providing strong guarantee for continuous improvement of process capability. We have advanced production equipment and production lines in the industry, realizing automated batching, continuous automated operation of dense refining, open refining, extrusion, vulcanization and finished products, with a high degree of automated production in the workshop. The company has few other independent production workshop in the same industry, complete production equipment, for homemade equipment, R & D equipment and production equipment accessories production provides a favorable advantage of order at any time, at any time to make, at any time to modify, independent research and development of a variety of production equipment for the industry is unique. With perfect experimental test equipment, testing laboratory area of 2,000 square meters, with 35 sets of testing equipment, including single combustion experimental furnace, water vapor transmission system, liquid chromatograph, thermal conductivity meter, sulfurization meter, smoke density tester, oxygen index tester, with the national standard of the full range of indicators testing capabilities, while having a small test, Chinese production line of three.

Refinement for effective implementation

Huamei always adheres to the management concept of “standardization, innovation, safety and high efficiency”, compiles the “standardization manual”, and formulates the “post technical operation rules” for each post, standardizes the process and quality standards of each link, and strengthens the awareness of “cost, expense and benefit”. To strengthen the awareness of “cost, expense, benefit”, to achieve the organic combination of system, process, responsibility, goal, supervision, assessment, rewards and punishments, incentives. Effective control of procurement of raw materials, technology, production process, quality inspection, will be precise, accurate, detailed, strict implementation of each link with the process control. The operation site has implemented 6S management, Kanban management, target-oriented management, and on-site control of the operation process. The implementation of the product traceability system, the establishment of a one-item-one-code system, so that each product can be traced back to ensure the stable improvement of product quality, and become an important guarantee of the company's performance, the product delivery of qualified rate is always maintained at 100%.

"3X3 ”Service System Advantage

The company attaches importance to customer relationship management, the implementation of “create satisfaction with sincerity” service concept, the establishment of pre-sales, sales, after-sales “3X3” service system. Pre-sale service to provide users with product performance, use, effect and other professional knowledge of the consultation and recommendation, in order to achieve the best combination of economic and use of the effect, customers are invited to the production base for observation, the use of efficacy and installation of the most intuitive understanding of the service; in-sale service to allow customers to use high-quality insulation materials, according to the needs of the customer, to send a professional installation engineers to the project site to guide the production and installation of the prototype room to provide customers with a quicker service, to ensure that the delivery period requirements, to ensure that the delivery date of the 3X3 “service system. faster service, to ensure that the supply period requirements and the progress of the project, for the site of the product installation of difficult problems, rapid response, by professionals to put forward reasonable solutions; after-sales service to completely eliminate customer worries, at any time to accept customer feedback, given to the rapid acceptance of the problems that arise in 1 working day to give a reply, and optimize the complaint handling process to improve customer satisfaction, the establishment of detailed Customer file management, annual tracking of product use.

social value

The company takes social responsibility as a duty-bound responsibility. Over the years, in order to support the development and construction of central and western China, the company has invested in Sichuan, Jiangxi investment in factories, help poverty alleviation, absorbing local employment 770 people; 2008 Wenchuan earthquake in Sichuan, the company enthusiastically donated 390,000 yuan; in 2018, the company took out a part of the enterprise development of residential areas as a public service of the enterprise, to give each villager full subsidies for the purchase of 10 square meters of housing, the subsidies total amount of 68.58 million yuan; during the Spring Festival in 2020, gratuitously donated Huamei rubber insulation materials and supporting products worth more than 2 million yuan to support the construction of Wuhan Leishenshan and Vulcanshan hospitals, and the company also took the initiative to donate 50,000 yuan to support the local government's all-out efforts to fight the epidemic. From 2011, and Dacheng Volunteer Association to organize and carry out the “love trip” volunteer activities, bear all the costs of the activities, so far has been held seven; the company developed the tail gas desulfurization and dust removal, flue gas purification and treatment technology and equipment free of charge to the same industry to promote the application. Up to now it has accumulated donations and goods worth 102 million

FACTORY LIBRARY

Copyright © Huamei Energy-saving Technology Group Co., Ltd. All Rights Reserved | Sitemap | Privacy Policy

Insulation solutions LIST: Insulation solutions LIST